- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

2026 Best Slip Masterbatch Options for Enhanced Performance and Efficiency?

In today's competitive manufacturing environment, the choice of slip masterbatch is crucial. Industry expert Dr. Emily Chen once stated, "The right slip masterbatch can significantly improve product efficiency." This highlights the importance of selecting the appropriate materials for enhanced performance. Slip masterbatch primarily reduces friction, improving the flow characteristics of plastic products.

As manufacturers strive for optimization, the need for high-quality slip additives becomes evident. Many options are available, but choosing the best ones can be challenging. Not all slip masterbatch formulations deliver consistent results. Some may not provide adequate slip in every application, leading to potential pitfalls in production.

In this exploration of the 2026 best slip masterbatch options, we will uncover which products truly stand out. Understanding the specific needs of your application is vital. This investigation aims to tackle common concerns and reflect on ongoing advancements in slip masterbatch technology. By doing so, we can push for greater efficiency and performance in the industry.

Understanding Slip Masterbatch and Its Importance in Plastics

Slip masterbatch plays a crucial role in enhancing the performance of various plastic products. It contains additives that reduce friction between surfaces. This reduction leads to better handling and processing. Moreover, it prevents sticking during manufacturing. Without slip masterbatch, many plastics would face challenges in production and usage.

The importance of slip masterbatch cannot be overstated. It improves the flow characteristics of plastics. Manufacturers benefit from smoother production processes. Additionally, the end products exhibit improved durability and surface finish. However, not all slip masterbatches are created equal. Some may not integrate well, leading to inconsistent performance. It's essential to select the right type for specific applications.

While the advantages seem clear, some challenges persist. For example, some additives can affect the color and clarity of plastics. This alteration may not be desirable in all cases. Furthermore, over-reliance on slip masterbatch might mask underlying issues. A careful evaluation of each application is necessary. Balancing efficiency with quality remains a constant challenge for manufacturers.

Key Features of Advanced Slip Masterbatch Options for 2026

In 2026, slip masterbatches are becoming essential for various industries. These additives improve surface properties in plastics, speeding up production processes. They also reduce friction, which enhances performance. Key features include excellent dispersion, effectiveness at low dosage, and compatibility with various polymers. This allows for seamless integration into existing formulations.

One notable aspect is the varying formulations available. While some options may provide enhanced lubricity, others might affect clarity or color. Balancing these characteristics is crucial. Manufacturers must evaluate the specific needs of their applications. Small changes in formulation can lead to significant differences in the final product’s performance.

Considering environmental impact is also vital. Some advanced slip masterbatches may contain additives that raise sustainability concerns. It’s essential to research and choose materials that align with eco-friendly practices. Users must remain vigilant about their choices and explore alternatives to ensure enhanced performance without compromising environmental responsibilities.

Comparative Analysis of Leading Slip Masterbatch Brands

The slip masterbatch market has been evolving rapidly. Recent studies show that the demand for high-performance slip masterbatches is increasing, with a projected growth rate of 5.5% from 2023 to 2026. This growth is driven by the rising need for improved processing efficiency and enhanced surface quality in various applications.

When comparing leading slip masterbatch options, critical factors include performance metrics and efficiency. Some analyses have revealed that certain products exhibit lower coefficients of friction, enhancing product handling and reducing wear in machinery. Current reports indicate that formulations combining polyethylene and specialized additives lead to superior slip characteristics, yet some brands still struggle with consistency in performance. These discrepancies often stem from variations in raw material quality and production practices.

In terms of overall efficiency, integrating the right slip masterbatch can reduce energy consumption during processing. Efficiency gains can reach up to 15% when using the optimal formulation. However, it's essential to note that a one-size-fits-all solution does not exist. Each application requires specific adaptations. Brands must focus on continuous research and development to stay competitive in this dynamic market.

Performance Metrics: Evaluating Efficiency Gains with Slip Masterbatches

Slip masterbatches offer exciting potential for improving performance in various applications. These additives enhance the slip properties of polymers, reducing friction during processing. In turn, this can lead to smoother surfaces and better overall product quality. Evaluating efficiency gains is crucial. Understanding how these masterbatches work is key to maximizing their benefits.

When considering performance metrics, focus on specific attributes. For instance, slip masterbatches can significantly lower the coefficient of friction. This reduction results in fewer processing issues, such as jamming or sticking. Additionally, they can improve the surface finish and aesthetics of products. However, not every application responds uniformly to these enhancements. Continuous experimentation is essential for determining the best formulations that suit different materials.

Testing various concentrations of slip masterbatches can yield varying results. Sometimes, too high a concentration can lead to unexpected softness or deformity. A delicate balance is necessary to achieve the desired characteristics. Proper evaluation through real-world testing helps refine these formulations. It ensures that efficiency gains do not come at the expense of product integrity.

2026 Best Slip Masterbatch Performance Metrics

This chart represents the performance gains achieved by using various slip masterbatches across key metrics. Each metric shows a measurable improvement in performance efficiency, demonstrating the advantages of utilizing high-quality slip additives in production processes.

Future Trends in Slip Masterbatch Technology and Applications

The future of slip masterbatch technology is evolving rapidly. As industries seek improved efficiency, manufacturers are focusing on advanced formulations. These new slip agents enhance surface properties without compromising mechanical strength. This balance is crucial for applications like packaging and automotive parts.

Recent studies show promising trends in natural and biodegradable materials. Many manufacturers are exploring sustainable options. However, the challenge remains in achieving the desired slip performance. Some products may still leave room for improvement in terms of durability and application versatility.

Innovation in processing techniques is also noteworthy. Techniques such as melt blending and twin-screw extrusion are gaining attention. These methods offer better dispersion of slip agents. Yet, their implementation can be tricky and costly for some manufacturers. There’s a need to reflect on the balance between cost and performance in slip masterbatch development.

2026 Best Slip Masterbatch Options for Enhanced Performance and Efficiency

| Slip Agent Type | Recommended Dosage (%) | Effect on Friction Coefficient | Recommended Applications | Supplier Availability |

|---|---|---|---|---|

| Erucamide | 0.5 - 2.0 | Low to Moderate | Flexible films, caps | Widely available |

| Stearamide | 0.3 - 1.5 | Moderate | Agricultural film, packaging | Limited availability |

| Octadecylamine | 0.2 - 1.0 | Low | Industrial liners, coatings | Common |

| Polyethylene Glycol (PEG) | 2.0 - 5.0 | Moderate to High | Pharmaceutical packaging, food films | Easily accessible |

| Silicone-Based Additives | 0.1 - 0.8 | Very Low | Non-stick surfaces, medical devices | Specialized suppliers |

Related Posts

-

Discover How Slip Masterbatch Revolutionizes Plastic Processing Efficiency

-

Unlocking the Benefits of Anti Block Masterbatch: Revolutionizing Plastics with Enhanced Performance

-

Unlocking Creativity: How Special Effect Masterbatches Transform Modern Plastics with 30% Enhanced Visual Appeal

-

10 Essential Tips for Choosing the Right Polyethylene Masterbatch for Your Projects

-

Top 5 Surya Masterbatch Options for Enhanced Plastic Performance

-

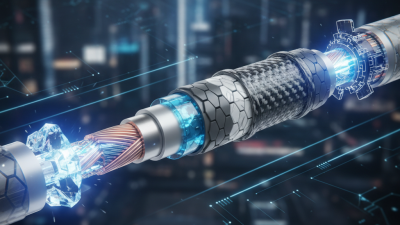

What is a Compound Cable and How Does It Improve Electrical Connections