- Home

- Masterbatch

- Additive Masterbatch

- Anti-Block Masterbatch

- Anti-Fog Masterbatch

- Anti-Microbial Masterbatch

- Anti-Oxidant Masterbatch

- Anti-Static Masterbatch

- Anti-Termite & Rodent Masterbatch

- Desiccant / Anti-Moisture Masterbatch

- Optical Brightener Masterbatch

- Flame Retardant Masterbatch

- Slip Masterbatch

- Polymer Processing Aid (PPA) Masterbatch

- UV Masterbatches

- VCI Additive Masterbatch

- Filler Masterbatch

- Black Masterbatch

- White Masterbatch

- Color Masterbatch

- Mono Masterbatches

- Special Effect Masterbatches

- EVA Masterbatch

- OXO Biodegradable Masterbatch

- XLPE Masterbatch

- Cable Masterbatch

- Nylon Masterbatch

- TPU Masterbatch

- Additive Masterbatch

- Compound

- Market

- Company

- Blog

- Contact Us

What is a Compound for Plastic and How Does It Work?

In the realm of modern manufacturing, the term "compound for plastic" holds significant weight. These compounds are crucial for enhancing the properties of plastic materials. According to Dr. Emily Carter, a leading expert in polymers, "Compounds for plastic can make ordinary materials extraordinary." This underscores the transformative power of these additives in various applications.

The functionality of a compound for plastic goes beyond mere improvement. It allows manufacturers to create products that are more durable, flexible, and sustainable. For example, adding specific compounds can reduce the brittleness of plastics, which is a common challenge. However, not all compounds deliver the desired results. Finding the right balance of additives can be tricky. It requires meticulous research and development.

In recent years, the industry has faced increasing scrutiny over environmental impacts. It’s crucial to question the sustainability of certain compounds. Some innovations, although effective, may also raise concerns about biodegradability. As we explore "compound for plastic," it's essential to weigh benefits against potential drawbacks. This reflection can lead to better choices in material science.

Definition of Compounds in Plastic Manufacturing

Compounds in plastic manufacturing play a crucial role in determining the final properties of plastic products. These compounds are mixtures of various materials, including polymers, fillers, additives, and modifiers. They enhance performance, appearance, and durability. The combinations can vary widely, leading to different qualities in the finished product.

When creating a plastic compound, manufacturers often use fillers to improve strength and reduce weight. Additives can provide color, UV resistance, or flame retardance. Each ingredient has a specific purpose. Yet, the formulation process can be tricky. Balancing cost, performance, and eco-friendliness requires careful thought. Sometimes, the ideal compound may not be feasible, prompting reflections on compromises.

**Tip:** Always test small batches of compounds before full-scale production. This practice can help identify any potential issues early on.

Understanding these concepts is essential for anyone involved in plastic production. As technology evolves, new compounds emerge, driving innovation. However, it's critical to stay informed about the environmental impact of these materials.

**Tip:** Keep an open mind about alternative materials. Explore options that minimize environmental harm without sacrificing quality.

Types of Compounds Used in Plastic Production

Compounding is crucial in plastic production. Various types of compounds enhance the properties of plastic materials. Common compounds can be categorically defined into additives, fillers, and reinforcements.

Additives include stabilizers, plasticizers, and colorants. For instance, common plasticizers, like phthalates, improve flexibility. Reports indicate that about 80% of plastic products utilize some form of plasticizer. Fillers, such as calcium carbonate and talc, reduce production costs while improving mechanical properties. Studies show that using fillers can decrease overall material costs by approximately 30%.

Reinforcements, like fiberglass, enhance strength and rigidity in plastics. This is particularly popular in automotive and construction applications. However, the selection of compounds must be done thoughtfully. Using too many additives can compromise the material's recyclability. Thus, the balance of performance and sustainability is a persistent challenge in the industry. Adapting to new regulations and consumer demands also complicates the compounding strategy.

Types of Compounds Used in Plastic Production

How Compounds Enhance Plastic Properties

Compounds play a crucial role in enhancing the properties of plastic materials. These compounds can be additives, fillers, or modifiers that improve performance. For instance, a compound might increase a plastic’s strength or flexibility. Some compounds can also enhance resistance to UV light or chemicals. Each compound serves a unique purpose and acts at the molecular level.

When creating many plastic products, understanding how these compounds work is vital. Certain additives can boost the plastic’s durability. Others focus on making the material more lightweight. This transformation is essential for industries like automotive and consumer goods. However, not all compounds work as intended. Sometimes, they can even compromise the material's integrity. The balance between performance and long-term stability is challenging to achieve. It requires constant testing and innovation to ensure desired outcomes. Misjudging a compound's impact can lead to failures that are costly in terms of time and resources.

The Role of Additives in Plastic Compounds

Plastic compounds are created by mixing polymers with various additives. These additives play a crucial role in altering the properties of the base plastic. For instance, additives can enhance strength, flexibility, or resistance to environmental factors. They tailor the performance of plastics to meet specific application needs.

One common category of additives is plasticizers. These substances increase flexibility and workability. Without them, some plastics would be too brittle. Another important additive is a stabilizer, which protects the material from degradation due to heat or light. This prolongs the life of plastic products.

Tips: When selecting additives, consider the end-use of the plastic. Different applications require different properties. Also, ensure that the additives are compatible with the base polymer for optimal performance. Experimenting with ratios can lead to unexpected results. Don’t overlook the importance of testing your compound rigorously.

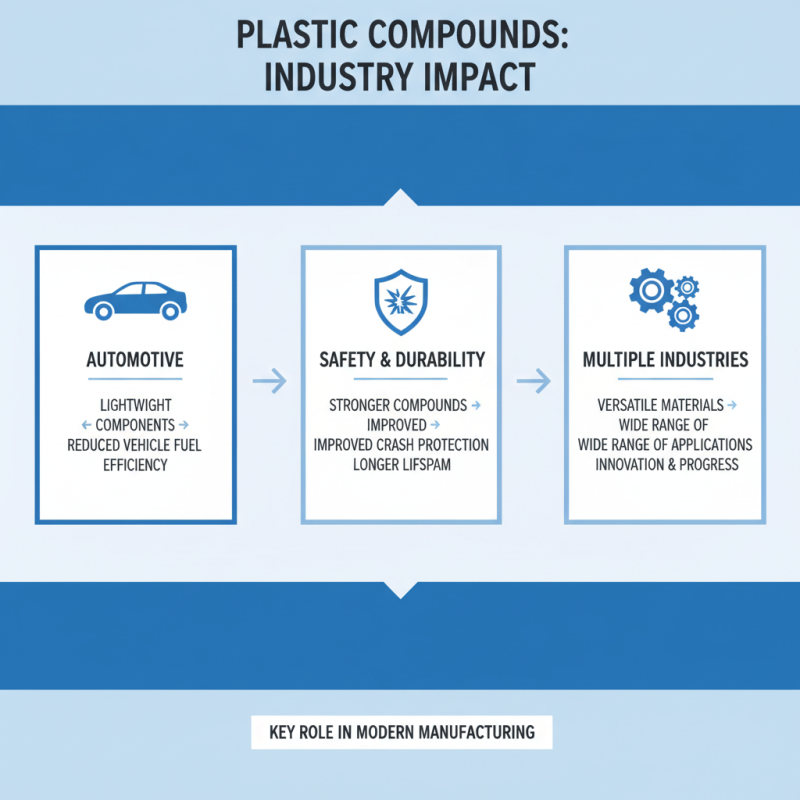

Applications of Plastic Compounds in Various Industries

Plastic compounds play a crucial role in multiple industries. Automotive manufacturers, for instance, utilize these materials for lightweight components. This reduces vehicle weight, enhancing fuel efficiency. Stronger compounds improve safety and durability in crash situations.

In the packaging sector, plastic compounds are equally essential. They provide durability and flexibility for various products. These compounds can be molded into different shapes, making them perfect for containers. However, some environmental concerns arise from plastic use. This prompts the ongoing search for eco-friendly alternatives.

Electronics also rely on plastic compounds. They create protective casings and parts for devices. These compounds help reduce weight and provide insulation. Yet, the disposal of electronic devices poses a recycling challenge. Striking a balance between utility and sustainability remains essential for future developments.

Related Posts

-

Top 5 Surya Masterbatch Options for Enhanced Plastic Performance

-

Unlocking the Benefits of Anti Block Masterbatch: Revolutionizing Plastics with Enhanced Performance

-

Top 5 Cable Compounds: Key Types and Their Applications Explained

-

2026 Best HDPE Compound Options for Your Projects How to Choose?

-

How to Choose the Right Black Masterbatch for Your Plastic Applications

-

Exploring the Benefits of Compound Masterbatch: Industry Trends and Performance Metrics for 2024